Champaran, West

This is a collection of articles archived for the excellence of their content. |

YEAR-WISE DEVELOPMENTS

2021

Manufacturing startups

August 13, 2021: The Times of India

From: August 13, 2021: The Times of India

From the days when indentured labourers sailed to Mauritius, Fiji and the West Indian islands, labour has been West Champaran’s most famous export. But in the months since the first Covid lockdown brought its migrant workers back home, this Bihar district has started shipping tracksuits to Ladakh and jackets to Spain, and seems on its way to becoming a garment industry hub. How one of India’s poorest and most backward districts turned adversity into opportunity is quite a story.

Long march home

April 2020 is a time Idrish Ansari and Archana Kushwaha will never forget. They were among the more than 1 lakh workers who braved heat and hunger to return to their villages in West Champaran during last year’s lockdown. Ansari quit Delhi and Kushwaha Surat with no hopes, knowing their district won’t have work for them. Both are skilled workers, and Bihar with its low urbanisation and industrialisation simply does not have much employment. When they entered the district, the returning migrants were corralled in quarantine camps. It was a bleak time but turned out to be for the best as the district administration acted swiftly to avert the looming human crisis.

Putting skills together

Knowing that many of the workers had considerable industrial skill and experience, West Champaran district magistrate Kundan Kumar started a skill-mapping programme while they were still in quarantine. It gradually grew into a database of more than 80,000 workers. “Just to give an example, we had people with expertise in all aspects of jeans production, from selecting yarn to cutting the fabric and selling the product in the market,” Kumar said. He asked the workers to see if their employers would relocate some work to West Champaran. When that didn’t work out, he encouraged them to start production on their own.

From silos to startups

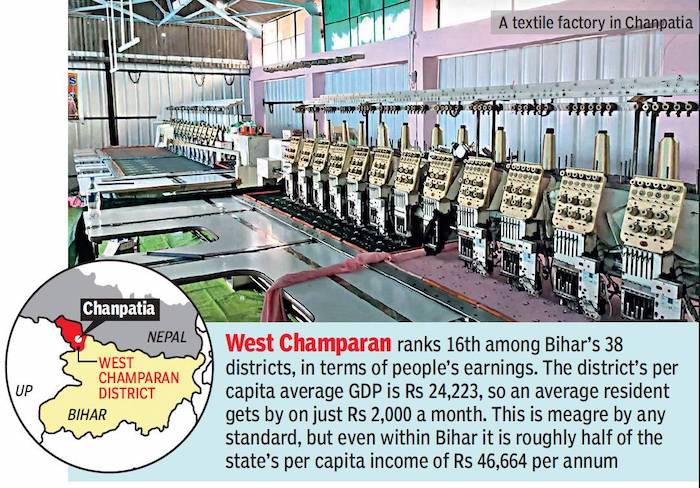

The workers wanted to set up a cluster of ancillary businesses needed for garment manufacturing. As arranging land was difficult, empty Bihar State Food Corporation godowns at Chanpatia, 17km from district headquarters Bettiah, were turned into the ‘Chanpatia Startup Zone’. But the workers had no money of their own to buy machinery and raw material, and banks in Bihar aren’t keen on lending. For India as a whole, banks lend 72% of the money they get as deposits, but in Bihar, only 38% of the money raised from depositors is lent out. As the startup dream would have collapsed without loans, Kumar arranged meetings between the workers and banks. “Today these startups have got about Rs 6.5 crore of credit,” he said.

The loans enabled them to buy power-looms, computerised embroidery machines, lasers to cut jeans, and other machinery from old production centres, and even import some equipment.

Not just jeans but brands

As first-time sellers, the workers needed distinctive branding. Some of them chose easy names like Champaran Creation, Bihar Garment or simply WC (for West Champaran), but there’s also the foreign-sounding Lisso targeted at a wider market.

“There is enough demand from the local market in Bihar, eastern UP and Nepal. Although Nepal, which is less than 50km from here, is in lockdown, many traders have expressed interest,” said Navneet Raj, an IT professional whose ADR Shirts makes about 5,000 shirts a month and has orders from Gopalganj district in Bihar as well as retailers in UP and Nepal. Archana Kushwaha’s Champaran Creations has sold over 16,000 sarees. Idrish Ansari has sold more than 70,000 leggings.

The 50-odd startups in Chanpatia employ more than 700 people making jackets, tracksuits, shirts, sarees, dupattas, sanitary napkins, etc. “So far they have sold items worth Rs 10.5 crore,” said Kumar. “Over 40,000 tracksuits have been sent to Ladakh, 5,000 jackets to Spain and two steel manufacturers are setting up factories to supply products to South Africa and Bhutan through their previous employers in Delhi.”

There are about 50 more startups in other parts of the district, said Kumar. One of them is a workshop run by a family that returned from Anantnag. “They are manufacturing cricket bats under the WC brand.”

Chanpatia is a success story that shows how government intervention can turn lives around. Impressed by the ‘Chanpatia model’, the Bihar government is assessing its feasibility for other districts. Maybe, it will be the seed that starts Bihar’s transformation.